The vibrating screen is one of the main equipment in the compound fertilizer industry, which is generally used for the classification and screening of finished compound fertilizer, and is also suitable for the screening of mining, coal mining, metallurgy and other industries. The machine is generated by vibrating motor and spring vibration, vibration ratio is small, high frequency, to ensure that the material has greater kinetic energy and inertia. In addition, the machine also has the advantages of small size, convenient operation, reliable work and so on.

- Structure and working principle:

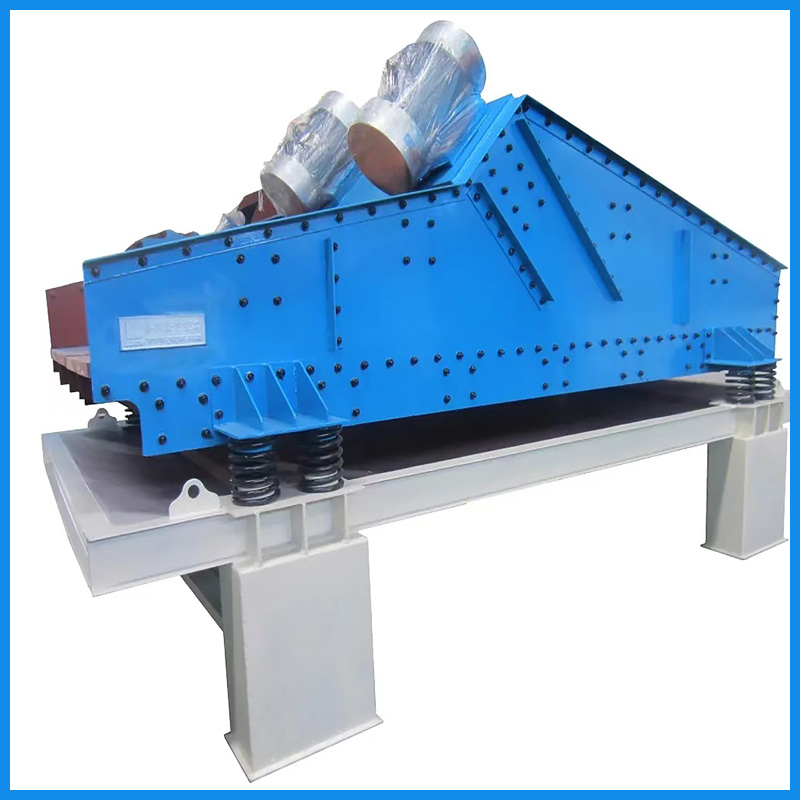

- Structure: It is mainly composed of vibration motor support spring, vibrating screen body, etc.

- Working principle: When the motor is energized and rotated, due to the role of the eccentric block at both ends of the motor, the unbalanced centrifugal inertia force (exciting force) caused by the screen box linear vibration on a certain steering wheel, the material is bounced on the screen surface jumping, and because the screen box and the horizontal plane into a certain Angle (inclined installation), so the material under the action of elasticity and gravity, along the parabolic trajectory on the screen surface jumping forward. And complete the continuous automatic unloading process.

二、Operation and maintenance:

1. The vibration motor should be firmly and reliably installed on the screen box, connected with high-strength bolts, and often check the situation of the connected parts.

2. After the vibrating screen is installed in place, the cable should not collide or friction with the vibrating body.

3. There should be no conductive dust and flammable and explosive products in the use environment, and pay attention to protect the motor to prevent the corrosion of granular fertilizer.

4. The screen should be started without load, and feed can be started after the screen runs smoothly. The feed should be stopped before stopping, and the material on the screen surface should be drained before stopping.

5. The feed tank should be as close as possible to the feed end of the screen body, and the feed should be distributed along the full width of the screen as far as possible, and the direction is consistent with the direction of the material running on the screen surface, so as to obtain the best screening effect. The maximum drop from the feeding point to the screen surface is not more than 500mm to ensure the minimum impact of the material on the screen surface.

6. Pay attention to check and tighten the connection frequently during operation.

7. The accumulation of materials should be prevented during operation. If there is accumulation, it should be cleaned up in time to prevent the motor from burning out due to mesh blockage and overload.

8. The working current of the motor is not allowed to exceed the value specified on the nameplate.