A Compound Fertilizer Rotary Drum Granulation Production Line is an advanced and highly efficient system for producing high-quality granulated fertilizers. This comprehensive production line is essential for modern agriculture, as it transforms raw materials into uniform, easy-to-apply fertilizer granules that contain a balanced mix of nutrients. The system is renowned for its large-scale output, flexibility in formulation, and the superior quality of its final product.

Process Flow

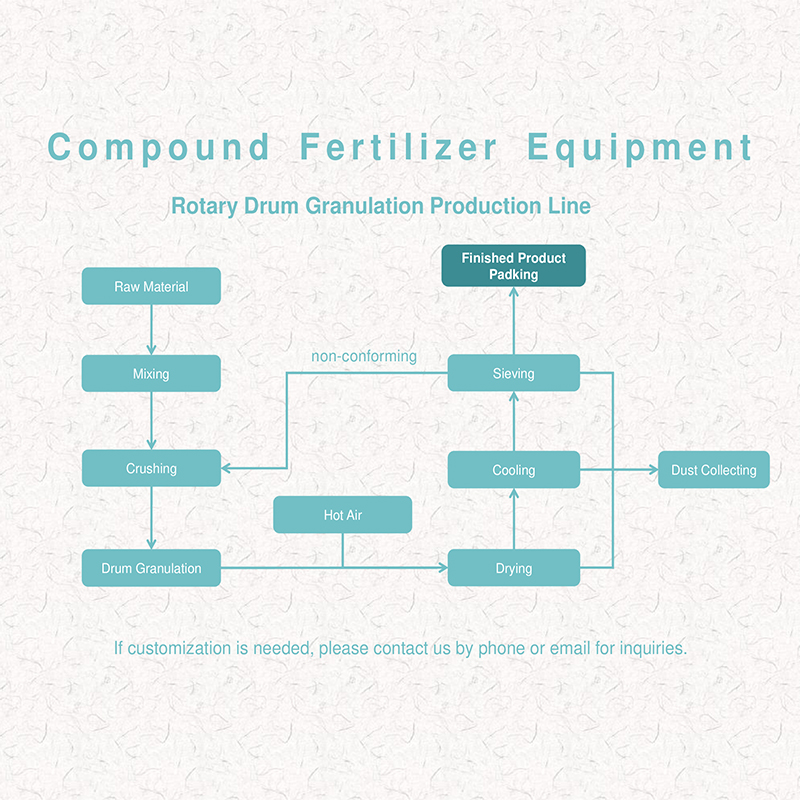

The production of compound fertilizers using this line involves a series of meticulously coordinated steps:

- Batching & Mixing: Raw materials, including nitrogen, phosphorus, and potassium (NPK) compounds, are accurately weighed according to a specific formula and then fed into a mixer to achieve a uniform blend.

- Granulation: The mixed materials are continuously fed into the rotary drum granulator, a key piece of equipment. As the drum rotates, a binding agent (often steam or water) is sprayed onto the tumbling powders. This action causes the particles to agglomerate and form spherical granules.

- Drying: The moist granules are transported to a rotary dryer. Hot air passes through the drum, reducing the moisture content to below 2%, which is necessary for long-term storage and preventing caking.

- Cooling: After drying, the hot granules are moved to a rotary cooler to bring their temperature down to a manageable level, preparing them for the next stage.

- Screening & Classification: The cooled granules pass through a rotary screen to separate them by size. Oversized granules are crushed and recycled back to the granulator, while undersized ones are also sent back for reprocessing. This ensures that only granules of the desired size move on.

- Coating & Packaging: The sorted granules can be coated with an anti-caking agent. Finally, the finished product is weighed and packaged for distribution.

Equipment Composition

A typical Compound Fertilizer Rotary Drum Granulation Production Line consists of the following key machines:

- Batching Machine: For precise weighing of raw materials.

- Belt Conveyor: Used for material transport between different machines.

- Rotary Drum Mixer: To thoroughly mix raw materials.

- Rotary Drum Granulator: The core machine for the granulation process.

- Rotary Dryer & Cooler: Essential for controlling moisture and temperature.

- Rotary Screen: For sorting granules by size.

- Crusher: To break down oversized granules for recycling.

- Coating Machine (Optional): To apply an anti-caking layer.

- Automatic Packaging Machine: For efficient packaging of the final product.

Characteristics

This production line is defined by several key characteristics that make it a preferred choice for large-scale fertilizer manufacturing:

- High Granulation Rate: The system can achieve a granulation rate of over 90%, maximizing raw material utilization and reducing waste.

- Uniformity & Quality: The granules produced have a high spherical shape and uniform particle size, which improves their physical properties, such as flowability and resistance to crushing.

- Large Production Capacity: The continuous nature of the process allows for high-volume output, making it suitable for large-scale commercial operations.

- Wide Application: The line can be adjusted to produce various fertilizer formulations, including NPK fertilizers, organic fertilizers, and trace element-enhanced fertilizers.

- Stable Operation: The robust design of the equipment ensures stable, long-term operation with minimal maintenance.

Application Fields

The applications of the Compound Fertilizer Rotary Drum Granulation Production Line are primarily focused on the agricultural sector. It is widely used to produce:

- Compound NPK Fertilizers: For balanced nutrient supply to various crops.

- Slow-Release Fertilizers: To provide nutrients over an extended period.

- Organic-Inorganic Fertilizers: Combining the benefits of both organic matter and chemical nutrients.

- Specialty Fertilizers: Tailored for specific crops like fruit trees, vegetables, and flowers.

This technology is crucial for modern farming, as it helps improve soil health, increase crop yields, and enhance the efficiency of nutrient application.

Key Selection Points

When selecting a Compound Fertilizer Rotary Drum Granulation Production Line, consider these critical factors:

- Production Capacity: Choose a line that matches your desired output. A smaller, semi-automated line is suitable for moderate production, while a large, fully automated line is necessary for high-volume commercial operations.

- Raw Material Type: Ensure the equipment is compatible with the specific raw materials you plan to use.

- Automation Level: Decide on the degree of automation that fits your budget and labor resources. High automation reduces labor costs but requires a larger initial investment.

- Energy Consumption & Efficiency: Opt for a line with high energy efficiency to lower long-term operating costs.

- Manufacturer’s Reputation & Service: Choose a reputable manufacturer that offers comprehensive after-sales support, including installation, training, and spare parts availability.