A Compound Fertilizer Urea-Ammonia Granulation Production Line is a specialized and highly effective system used for producing high-quality compound fertilizers. This advanced production process is specifically designed to handle urea and ammonia, which are the main sources of nitrogen. The result is a fertilizer with a uniform granule size, excellent physical properties, and a balanced nutrient content, making it a critical asset for large-scale agricultural operations.

Process Flow

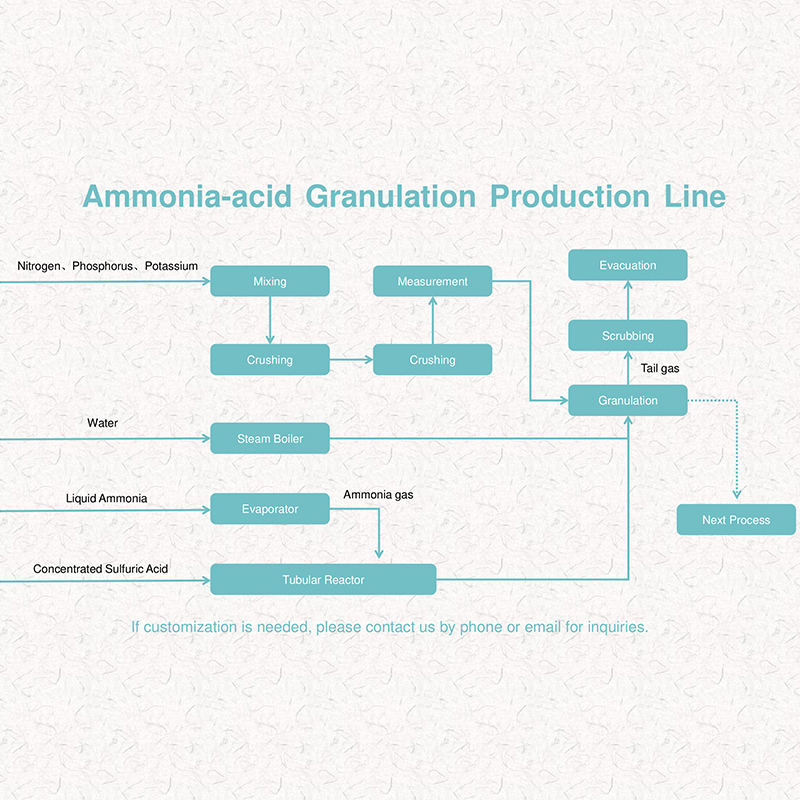

The production of compound fertilizers on this line follows a precise and integrated series of steps:

- Raw Material Preparation: Urea, ammonia, and other essential ingredients like phosphoric acid and potassium chloride are prepared and weighed according to a specific formulation. The liquids (ammonia, phosphoric acid) are often pre-heated and pressurized.

- Reaction & Granulation: The prepared raw materials are fed into a specialized ammoniation-granulation drum. This is the core of the process. Inside the drum, a series of chemical reactions occur as ammonia gas reacts with phosphoric acid and other components. Simultaneously, the mixing and tumbling action of the drum cause the materials to form uniform granules.

- Drying & Cooling: The moist, hot granules are then transferred to a rotary dryer. Hot air removes excess moisture, ensuring the granules are stable for storage. Following this, a rotary cooler brings the product temperature down to an ambient level.

- Screening & Classification: The cooled granules pass through a rotary screen. This step separates the product into three categories: oversized granules (which are crushed and recycled), undersized granules (also recycled), and the final product, which meets the specified size requirements.

- Coating & Packaging: The sorted granules may be coated with a protective or anti-caking agent to enhance their durability. Finally, they are weighed and packaged into bags for sale and distribution.

Equipment Composition

A typical Urea-Ammonia Granulation Production Line includes these key components:

- Proportioning & Mixing Systems: For accurate measurement and blending of solid and liquid raw materials.

- Ammoniation-Granulation Drum: The central piece of equipment where chemical reaction and granulation occur simultaneously.

- Rotary Dryer: Removes moisture from the granules.

- Rotary Cooler: Cools the granules for further processing and storage.

- Rotary Screen: Separates granules based on size.

- Crusher: Recycles oversized granules.

- Belt Conveyors: Transport materials throughout the production line.

- Packaging Machine: Automates the final bagging process.

Characteristics

This production line is distinguished by its unique features that ensure a high-quality final product:

- High Granulation Rate: It achieves a high rate of product formation, maximizing efficiency and minimizing waste.

- Uniform Granule Quality: The granules are uniform in size, spherical in shape, and possess excellent physical strength, which prevents crushing during transport and application.

- High Nutrient Concentration: The process allows for the creation of high-concentration NPK fertilizers, which are more cost-effective to transport and apply.

- Versatility: The line can be adapted to produce a wide range of fertilizer formulas to meet specific crop and soil needs.

- Process Stability: The system is designed for stable, continuous operation, ensuring consistent product quality and high output.

Application Fields

The Urea-Ammonia Granulation Production Line is a cornerstone of modern fertilizer manufacturing. Its primary applications are in the agricultural sector for the large-scale production of:

- High-Concentration Compound NPK Fertilizers: Essential for increasing crop yields and soil fertility.

- Tailored Fertilizers: Formulated to meet the specific nutritional requirements of various crops and soil types.

- Blended Fertilizers: Incorporating trace elements or slow-release agents to improve nutrient delivery efficiency.

This technology is critical for supporting global food production by providing farmers with effective and reliable nutrient sources.

Key Selection Points

When choosing a Urea-Ammonia Granulation Production Line, consider these important factors:

- Production Capacity: Select a line that aligns with your market demand and business goals. Underestimating or overestimating capacity can lead to inefficiencies.

- Raw Material Compatibility: Verify that the system is compatible with the specific raw materials and their chemical properties, especially the ammonia and acids.

- Automation Level: Determine the appropriate level of automation for your operational budget and labor resources. Higher automation reduces manual labor but requires a greater initial investment.

- Energy Consumption: Evaluate the energy efficiency of the equipment. A more efficient line will lead to lower long-term operating costs.

- Manufacturer’s Support: Choose a reputable manufacturer that offers comprehensive support, including installation, technical training, and reliable after-sales service.