An Organic Fertilizer Pan Granulation Production Line is a complete system designed for the efficient production of high-quality organic fertilizer granules. This technology utilizes the unique properties of a rotating disc to form uniform, spherical granules from powdered organic materials. It’s a popular choice for manufacturers who process a wide range of organic waste, including animal manure, crop stalks, and food waste, into valuable, nutrient-rich products for sustainable agriculture.

Process Flow

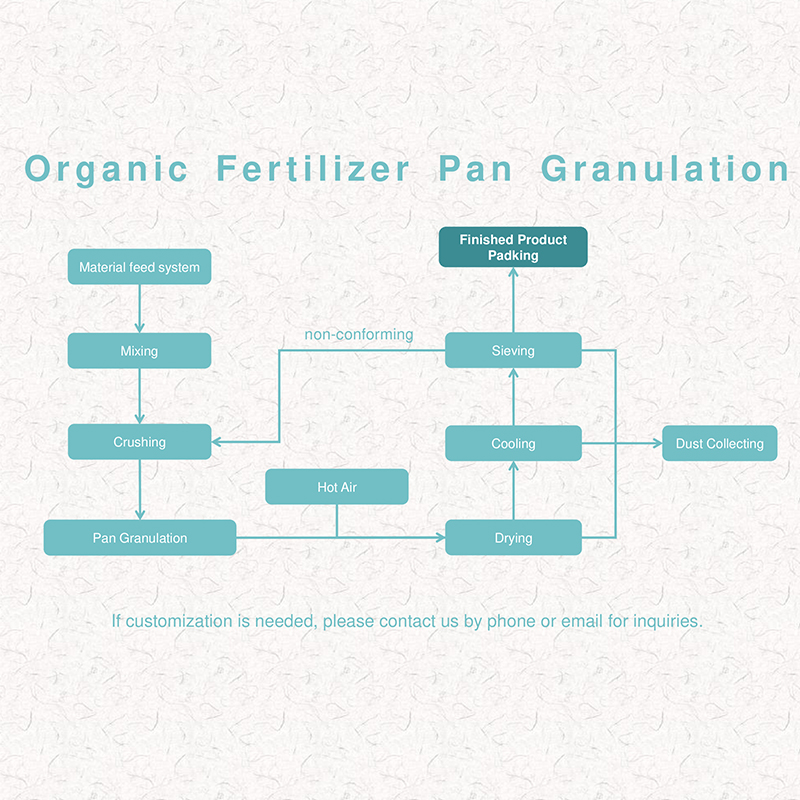

The production of organic fertilizer using a disc granulation line follows a precise and well-structured process:

- Raw Material Pre-treatment: Organic raw materials are first fermented to break down complex compounds and kill harmful bacteria. This fermentation is typically done in compost turning machines. After fermentation, the materials are crushed and screened to ensure a fine, uniform powder.

- Mixing & Granulation: The prepared organic powders are fed into a pan granulator, which is a large, tilted rotating disc. As the disc rotates, a small amount of water or a binding agent is sprayed onto the powder. The rotational force and a scraper within the pan cause the materials to tumble and roll, gradually forming small, dense spherical granules.

- Drying & Cooling: The newly formed granules, which are moist from the granulation process, are transferred to a rotary dryer. Hot air passes through the dryer, reducing the moisture content to below 15% for optimal storage. A subsequent rotary cooler then brings the temperature down to ambient levels.

- Screening & Classification: The cooled granules pass through a rotary screen to separate them by size. Oversized granules are crushed and returned to the granulation pan, while undersized ones are also sent back for reprocessing. This recycling ensures a consistent final product.

- Packaging: The finished, on-size granules are then weighed and packaged for distribution.

Equipment Composition

A typical Organic Fertilizer Pan Granulation Production Line includes these key machines:

- Compost Turner: For aerobic fermentation of raw organic waste.

- Crusher: To break down fermented materials into fine particles.

- Rotary Screen: For separating materials before and after granulation.

- Pan Granulator (Disc Granulator): The core machine for forming granules.

- Rotary Dryer & Cooler: Essential for controlling moisture and temperature.

- Belt Conveyors: For seamless transport of materials throughout the line.

- Automatic Packaging Machine: For efficient packaging of the final product.

Characteristics

The Organic Fertilizer Pan Granulation Production Line offers several distinct advantages:

- Versatility: It can process a wide variety of organic waste materials, making it highly adaptable for different sources like animal manure, sludge, and crop straw.

- Simple Operation: The system is relatively easy to operate and maintain, making it accessible to a wide range of manufacturers.

- High Granulation Rate: The pan granulator can achieve a high granulation rate, minimizing waste and maximizing efficiency.

- Uniform Granule Shape: It produces spherical, uniform granules that are aesthetically pleasing and easy to handle and spread.

- Low Investment: Compared to some other granulation technologies, the disc granulation line requires a lower initial investment, making it a cost-effective choice for medium-sized operations.

Application Fields

This production line is primarily used in the agricultural and environmental sectors for producing high-quality organic fertilizers. Its main applications include:

- Animal Manure Processing: Converting poultry, cattle, and pig manure into valuable fertilizer.

- Urban Waste Recycling: Turning municipal sludge and kitchen waste into useful products.

- Crop Residue Utilization: Processing crop stalks and other agricultural waste to improve soil fertility.

This technology is a vital component of the circular economy, transforming waste into resources that improve soil health and support sustainable food production.

Key Selection Points

When choosing an Organic Fertilizer Pan Granulation Production Line, consider these critical factors:

- Production Capacity: Select a line with an output that matches your raw material supply and market demand.

- Raw Material Type: Ensure the equipment is compatible with the specific organic materials you plan to process.

- Moisture Control: The moisture content of the raw materials is crucial for effective granulation. Look for a line that includes reliable pre- and post-processing equipment.

- Manufacturer Support: Choose a reputable manufacturer that provides comprehensive after-sales service, including installation, technical training, and readily available spare parts.

- Efficiency: Evaluate the overall energy consumption and labor requirements of the line to ensure it is cost-effective for your long-term operations.