A Controlled-Release Fertilizer Humic Acid Coating Production Line is a specialized and innovative system designed to produce advanced fertilizers. This technology applies a layer of humic acid—a natural, organic compound—onto the surface of conventional fertilizer granules. The humic acid acts as a functional coating, slowing down the release of nutrients to match a plant’s growth cycle. This process not only improves fertilizer efficiency and reduces nutrient waste but also enhances soil health, making it a cornerstone of sustainable and modern agricultural practices.

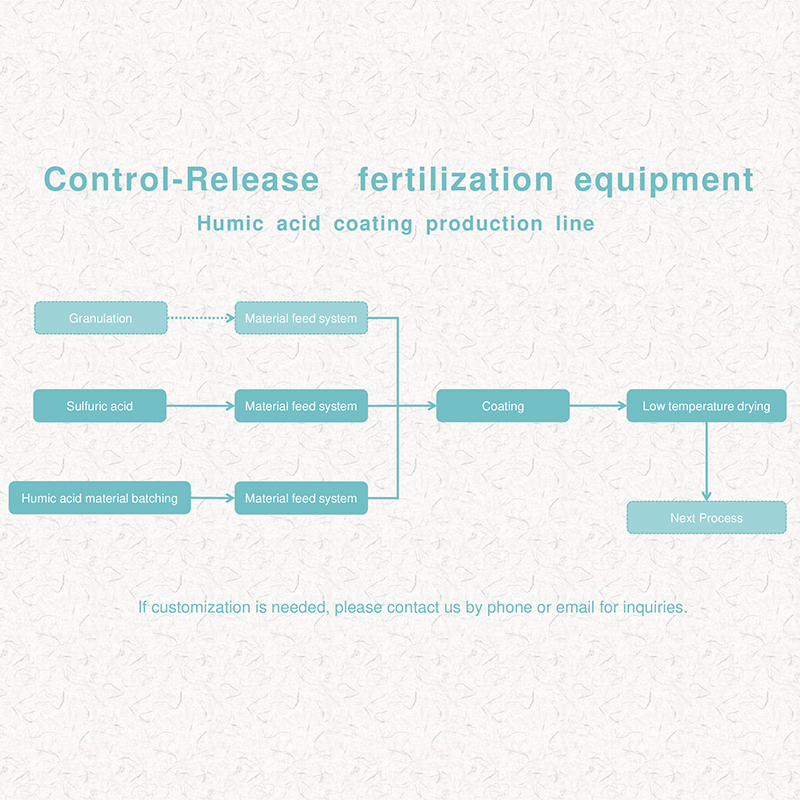

Process Flow

The production process for humic acid-coated controlled-release fertilizers is a precise, multi-step operation:

- Fertilizer Preparation: Standard fertilizer granules, such as NPK, urea, or DAP, are first pre-screened to ensure uniform size. They are then pre-heated to an optimal temperature to ensure the best possible adhesion of the coating.

- Humic Acid Slurry Preparation: A solution or slurry of high-purity humic acid is prepared in a dedicated mixing tank. The consistency and concentration are carefully controlled to ensure a uniform coating thickness.

- Coating: The pre-heated granules are fed into a rotary coating drum or a fluidized bed coater. The humic acid slurry is precisely sprayed onto the tumbling granules, forming a thin, even layer. This is the critical step where the controlled-release property is added.

- Drying & Solidification: The coated granules are immediately transferred to a rotary dryer or a fluidized bed dryer. Hot air passes through to remove moisture and cure the humic acid, creating a durable and stable coating that will not chip or break during handling.

- Cooling & Packaging: The dried granules are cooled to an ambient temperature. Finally, they are weighed and packaged, ready for distribution.

Equipment Composition

A typical Humic Acid Coating Production Line is composed of several key pieces of equipment:

- Raw Material Storage & Pre-treatment System: For holding and pre-screening the fertilizer granules.

- Humic Acid Mixing Tank: To prepare the coating solution.

- Rotary Coating Drum / Fluidized Bed Coater: The central unit for applying the coating.

- Rotary Dryer / Fluidized Bed Dryer: For drying and curing the coating.

- Belt Conveyors: To transport materials smoothly between stages.

- Automated Packaging Machine: For efficient and accurate final product packaging.

Characteristics

This production line is distinguished by several unique features that offer significant advantages:

- Enhanced Nutrient Efficiency: The humic acid coating ensures a gradual and consistent release of nutrients, which aligns with the plant’s absorption needs. This prevents nutrient leaching and reduces the number of fertilizer applications required.

- Improved Soil Health: Humic acid acts as a natural soil conditioner, improving soil structure, water retention, and microbial activity.

- Environmental Benefits: By minimizing nutrient runoff and groundwater contamination, the process helps protect the environment and supports sustainable agriculture.

- Versatility: The line can be easily integrated into existing fertilizer production facilities and is compatible with a wide range of fertilizer bases, including urea, DAP, MAP, and various NPK formulations.

Application Fields

The applications for humic acid-coated controlled-release fertilizers are diverse and crucial for modern agricultural and horticultural practices:

- Commercial Agriculture: Used for large-scale farming of crops like corn, wheat, and rice to ensure sustained nutrient delivery and maximize yields.

- Horticulture & Landscaping: Ideal for gardens, lawns, golf courses, and nurseries where a long-lasting, controlled nutrient supply is essential for consistent growth and appearance.

- High-Value Crops: Applied to fruit trees, vegetables, and ornamental plants to optimize growth and improve product quality.

Key Selection Points

When choosing a Humic Acid Coating Production Line, it is important to consider these critical factors:

- Coating Uniformity: A key performance indicator is the system’s ability to apply a consistent and even layer of humic acid. An uneven coating can compromise the controlled-release properties.

- Drying Efficiency: The drying and curing process is vital for the durability of the coating. Look for a system with high drying efficiency to prevent product clumping and ensure the coating is properly set.

- Compatibility: Ensure the equipment is compatible with the physical properties (size and shape) of the fertilizer granules you intend to coat.

- Automation Level: Choose a level of automation that aligns with your budget and operational needs. Automated systems offer greater precision and can reduce labor costs in the long run.

- Manufacturer’s Expertise: Select a reputable manufacturer with proven experience in this technology. A reliable partner will provide essential support for installation, training, and maintenance.