A Controlled-Release Fertilizer Polyurethane Coating Production Line is a state-of-the-art system designed to produce high-value fertilizers with precisely managed nutrient release. This advanced technology involves applying a thin, durable polyurethane (PU) polymer layer onto the surface of fertilizer granules. The PU coating acts as a semi-permeable membrane that controls the diffusion of nutrients into the soil, ensuring a steady, long-lasting supply for plants. This process dramatically improves fertilizer efficiency, minimizes nutrient loss, and reduces the environmental impact of farming.

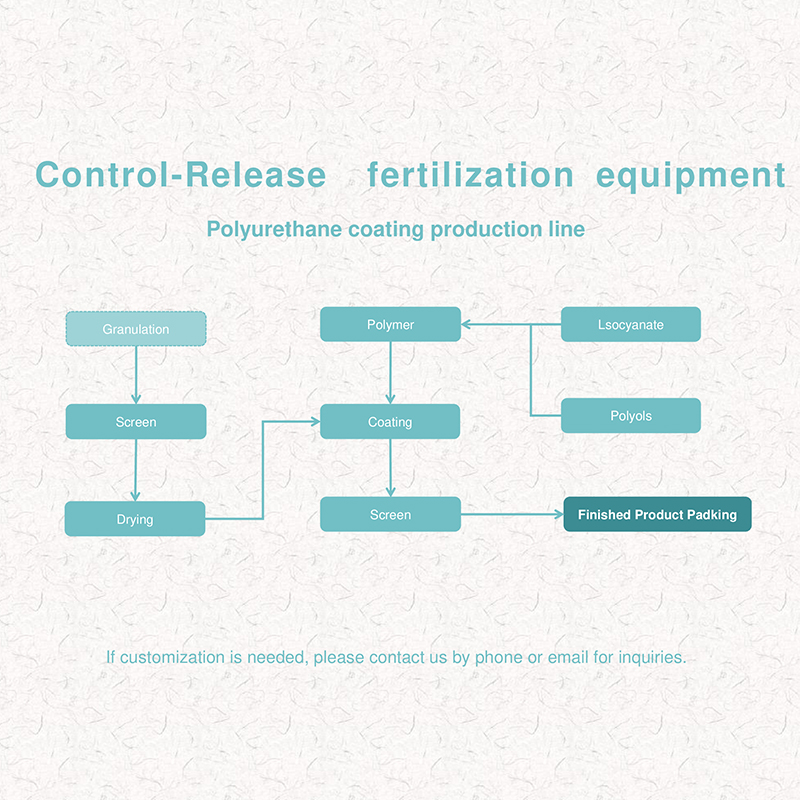

Process Flow

The production of polyurethane-coated, controlled-release fertilizers is a highly technical and precise process:

- Fertilizer Preparation: Standard fertilizer granules (e.g., urea, NPK) are carefully screened to a uniform size. They are then heated to a specific temperature in a pre-heating unit to ensure optimal adhesion of the polyurethane coating.

- Polymer Coating: The pre-heated granules are fed into a specialized fluidized bed coater. This machine uses a high-velocity airflow to suspend the granules, creating a fluid-like state. A mixture of polyol and isocyanate—the two components of polyurethane—is then sprayed onto the suspended granules, reacting on their surface to form a thin, seamless polymer shell.

- Curing: The coated granules remain in the fluidized bed or are transferred to a dedicated curing unit. Here, residual solvents evaporate and the polyurethane coating is fully cured, achieving its final strength and permeability. The curing time and temperature are critical to controlling the future nutrient release rate.

- Cooling & Packaging: The finished, cooled granules are then screened to remove any clumps and are ready for packaging. Automated systems weigh and bag the final product, ensuring consistency.

Equipment Composition

A typical Polyurethane Coating Production Line includes the following key components:

- Fluidized Bed Coater: The central machine where the coating process occurs. Its design ensures a uniform coat on every granule.

- Polymer Dosing & Mixing System: For precise measurement and mixing of the polyol and isocyanate components.

- Air Handling Unit: Supplies the hot, dry air necessary for fluidization and curing.

- Screening Machine: Ensures the final product has a consistent size and no clumps.

- Material Conveyors: Transport granules throughout the system.

- Packaging Machine: For efficient and accurate final product packaging.

Characteristics

This specialized production line offers significant advantages over conventional methods:

- Precise Nutrient Control: The polyurethane coating can be engineered to release nutrients over a specific duration, from a few weeks to several months. This minimizes nutrient runoff and provides a more effective feeding schedule for plants.

- High Efficiency: The controlled-release mechanism can increase a fertilizer’s nitrogen efficiency by over 30%, meaning less fertilizer is needed to achieve the same result.

- Reduced Environmental Impact: By preventing nutrient leaching and runoff, the production line helps protect waterways and the environment.

- Durability: The finished granules are hard, dust-free, and resistant to crushing, making them easy to handle, transport, and apply.

- Versatility: The line can be adapted to coat various types of fertilizers, including urea, NPK, and trace mineral blends, to create a wide range of custom products.

Application Fields

Polyurethane-coated, controlled-release fertilizers are a premium product used in demanding agricultural and horticultural applications:

- High-Value Agriculture: Ideal for crops like fruits, vegetables, and ornamentals, where consistent nutrition is crucial for quality and yield.

- Turf & Landscaping: Widely used on golf courses, sports fields, and high-end residential lawns to maintain lush, healthy grass with fewer applications.

- Nurseries & Greenhouses: Provides a stable nutrient source for potted plants, reducing labor costs associated with frequent fertilization.

- Urban & Hydroponic Farming: Enables precise nutrient delivery in controlled environments, maximizing growth and efficiency.

Key Selection Points

When choosing a Polyurethane Coating Production Line, consider these critical factors:

- Coating Uniformity: The most important factor. The equipment must be able to apply an even, consistent coating to every granule to ensure a reliable release rate.

- Process Control: Look for a system with advanced controls for temperature, air flow, and polymer dosing. Precise control is essential for producing a high-quality product.

- Safety Features: Ensure the equipment meets all safety standards, especially since the polyurethane components are reactive chemicals.

- Energy Efficiency: Evaluate the energy consumption of the fluidized bed and heating systems, as this will be a significant long-term operating cost.

- Manufacturer Expertise: Choose a manufacturer with proven experience in this specific technology. Ask for references and a detailed breakdown of their after-sales support, including training and maintenance services.