A Powder Fertilizer Production Line is a straightforward and efficient system for manufacturing fertilizers in a fine, powdered form. Unlike granular fertilizers that require complex granulation and drying processes, this line focuses on the precise mixing and pulverization of raw materials to create a uniform, powdery product. Powder fertilizers are often preferred for specific applications, such as base fertilization, direct application in certain crops, or as a raw material for other fertilizer types. This technology is known for its simplicity, cost-effectiveness, and flexibility.

Process Flow

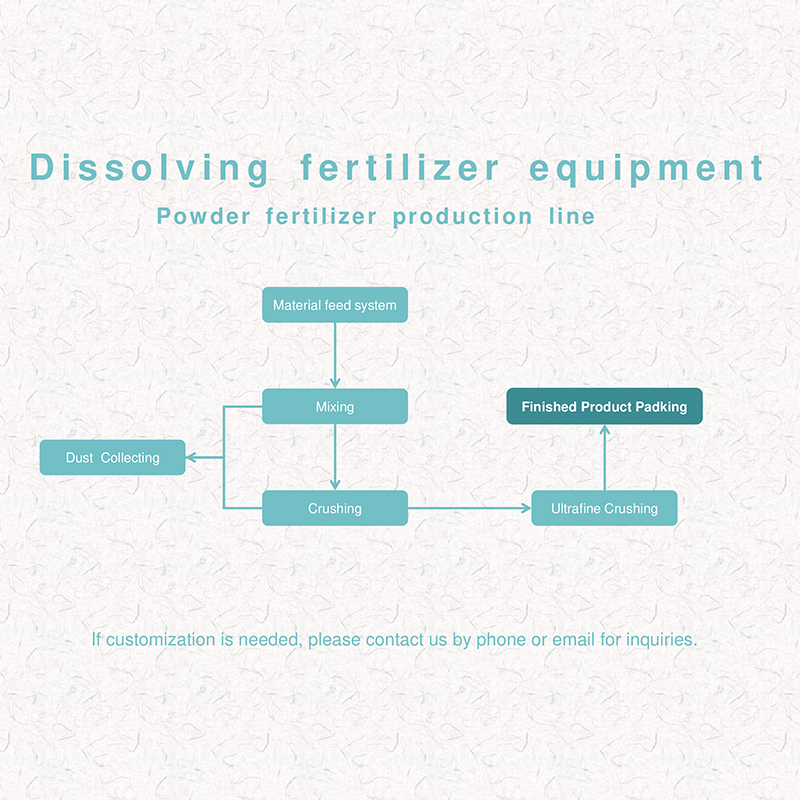

The production process for powdered fertilizers is designed for simplicity and efficiency:

- Batching & Crushing: Raw materials, which can be in solid or granular form, are accurately weighed by a batching system. They are then fed into a crusher or hammer mill to be broken down into a fine, uniform powder.

- Mixing: The crushed materials are transported to a powder mixer, where they are thoroughly blended to ensure a homogeneous distribution of nutrients. The mixer’s design is critical for preventing nutrient segregation and ensuring a consistent final product.

- Screening: The mixed powder can be passed through a vibrating screen to remove any oversized particles and ensure the final product has a consistent fineness.

- Packaging: The finished powder fertilizer is then weighed and packaged, typically using an automated packaging machine to ensure accuracy and speed.

Equipment Composition

A typical Powder Fertilizer Production Line consists of the following key machines:

- Batching Machine: For precise weighing of raw materials.

- Crusher or Hammer Mill: To pulverize raw materials into a fine powder.

- Powder Mixer: To achieve a uniform blend of all components.

- Vibrating Screen (Optional): To remove impurities and ensure a consistent particle size.

- Belt Conveyor: For transporting materials between different machines.

- Automatic Packaging Machine: For efficient and accurate final packaging.

Characteristics

The Powder Fertilizer Production Line has several distinct advantages that make it a compelling choice for certain applications:

- Simplicity and Low Cost: The line avoids complex, energy-intensive processes like granulation and drying, which significantly reduces the initial investment and operational costs.

- Flexibility: The system can handle a wide variety of raw materials and formulations, making it easy to switch between different fertilizer types and nutrient ratios.

- High Mixing Uniformity: Powder mixers are highly effective at creating a homogeneous blend, ensuring that every bag of fertilizer has a consistent nutrient content.

- Versatile Application: Powder fertilizers are ideal for direct application in specific crops, particularly those where quick nutrient absorption is desired.

Application Fields

Powder fertilizers are widely used in a variety of agricultural and horticultural settings:

- Base Fertilization: Often used as a base fertilizer and applied directly to the soil before planting.

- Greenhouses and Nurseries: The fine powder allows for easy mixing with potting soil or water for fertigation.

- Specific Crops: Ideal for crops like fruits and vegetables, where a quick and efficient nutrient supply is needed.

- Raw Material for Other Processes: Powder fertilizers can also serve as a key ingredient for producing liquid fertilizers or other blended products.

Key Selection Points

When choosing a Powder Fertilizer Production Line, consider these critical factors:

- Raw Material Compatibility: Ensure the crusher and mixer are compatible with the specific raw materials you plan to use, as different materials have varying hardness and mixing properties.

- Output Requirements: Select a line with a production capacity that meets your business needs. While the process is simple, a higher output requires more robust equipment.

- Mixing Uniformity: The quality of the mixer is paramount. Look for a mixer that can guarantee a high degree of uniformity to prevent nutrient segregation.

- Dust Control: The process can generate a significant amount of dust. Choose equipment with effective dust collection systems to ensure a clean and safe working environment.

- Manufacturer’s Reputation: Opt for a reputable manufacturer with a proven track record in building reliable fertilizer equipment.