A Controlled-Release Fertilizer Resin Coating Production Line is an advanced and highly specialized system used to produce fertilizers that release nutrients gradually over an extended period. This technology involves applying a thin, durable polymer resin coating to conventional fertilizer granules. The result is a more efficient fertilizer that minimizes nutrient loss, reduces application frequency, and provides consistent nourishment to plants throughout their growth cycle. This innovative process is crucial for modern, sustainable agriculture.

Process Flow

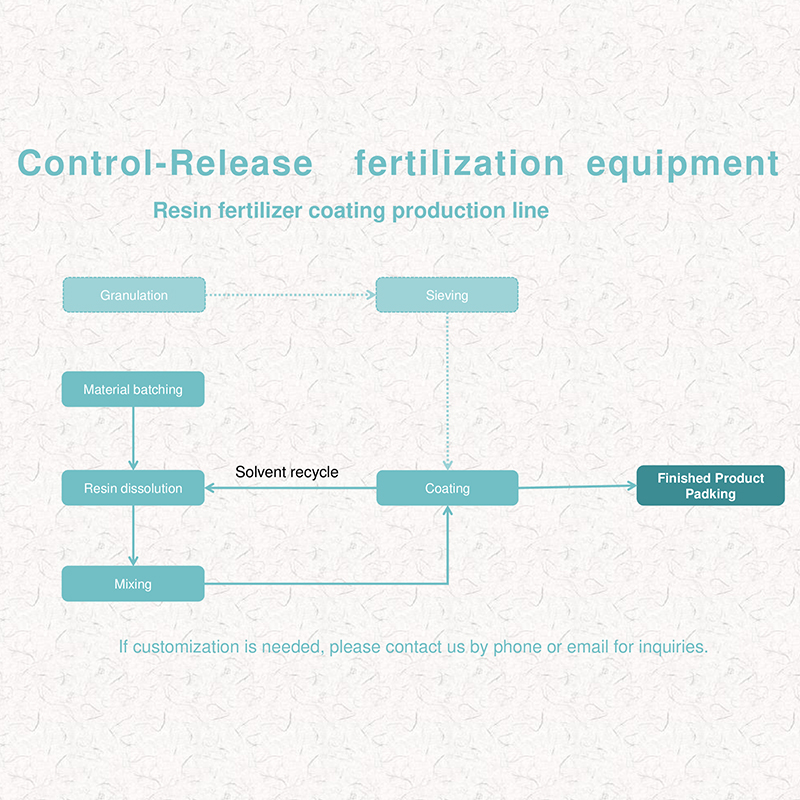

The production of resin-coated fertilizers is a meticulous process that ensures a uniform and high-quality coating:

- Fertilizer Preparation: Standard fertilizer granules (e.g., urea, NPK) are first screened to ensure they are of a uniform size and free of dust. This step is critical for achieving a consistent coating thickness.

- Pre-Heating: The granules are pre-heated in a rotary drum dryer or a pre-heating unit. The elevated temperature ensures the resin adheres properly and spreads evenly across the surface of each granule.

- Coating: The heated granules are then transferred to a specialized coating drum or a fluidized bed coater. Here, a liquid polymer resin is sprayed onto the tumbling granules. The rotation ensures that every granule is evenly coated with the resin solution.

- Curing & Cooling: After the resin is applied, the coated granules are moved to a curing unit where they are heated again to polymerize and harden the resin. This creates a strong, durable shell. Following this, the granules are cooled to solidify the coating completely.

- Screening & Packaging: The final coated granules are passed through a screen to remove any clumps or off-spec products. The finished, high-quality controlled-release fertilizer is then weighed and packaged for distribution.

Equipment Composition

A typical Resin Coating Production Line for controlled-release fertilizers includes these key machines:

- Fertilizer Screening Machine: For separating granules by size and removing dust.

- Pre-Heating Unit: To heat the granules before coating.

- Resin Coating Machine (Rotary Drum or Fluidized Bed): The core equipment for applying the polymer resin.

- Curing Unit: For hardening the resin coating.

- Cooling Unit: To cool and solidify the final product.

- Belt Conveyors: To transport materials between each stage.

- Packaging Machine: For efficient final packaging.

Characteristics

This production line is distinguished by its unique features that provide significant advantages over conventional fertilizer production:

- High Nutrient Use Efficiency: The controlled-release mechanism significantly reduces nutrient loss from leaching and volatilization, leading to a higher rate of nutrient uptake by plants.

- Reduced Application Frequency: Since nutrients are released slowly, farmers can apply the fertilizer once per season, saving labor costs and fuel.

- Uniform Product Quality: The coating process ensures each granule has a consistent, durable shell, leading to predictable nutrient release rates.

- Environmental Benefits: Lower nutrient leaching helps protect groundwater and reduces the environmental impact of fertilizer runoff.

- Customizable Release Profiles: The thickness and type of resin can be adjusted to create different nutrient release rates, tailoring the product to specific crop needs and climate conditions.

Application Fields

Controlled-release fertilizers produced by this line are essential for various modern agricultural and horticultural applications:

- High-Value Crops: Such as fruits, vegetables, and ornamental plants, where precise nutrient delivery is critical for quality and yield.

- Specialty Agriculture: Including turfgrass for golf courses, nurseries, and greenhouses.

- Sustainable Farming: By minimizing nutrient waste, this technology aligns with modern sustainable and eco-friendly farming practices.

- Soil Reclamation: Helps provide consistent nutrients to degraded soils, aiding in their recovery.

Key Selection Points

When choosing a Resin Coating Production Line, consider these critical factors:

- Coating Method: Decide between a rotary drum or a fluidized bed system. Rotary drums are better for high-capacity production, while fluidized beds offer more precise control over the coating thickness.

- Production Capacity: Select a line that matches your desired output. A higher capacity line will be more expensive but more efficient for large-scale operations.

- Resin Type & Compatibility: Ensure the equipment is compatible with the specific polymer resin you plan to use, as different resins have varying properties and application requirements.

- Automation Level: Assess the level of automation that fits your budget. Automated lines can reduce labor costs and improve consistency.

- Manufacturer’s Expertise: Choose a manufacturer with proven experience in producing this specialized equipment, as their technical support, training, and after-sales service will be crucial for successful operation.