technical specification

| Use: | Crushing of raw materials |

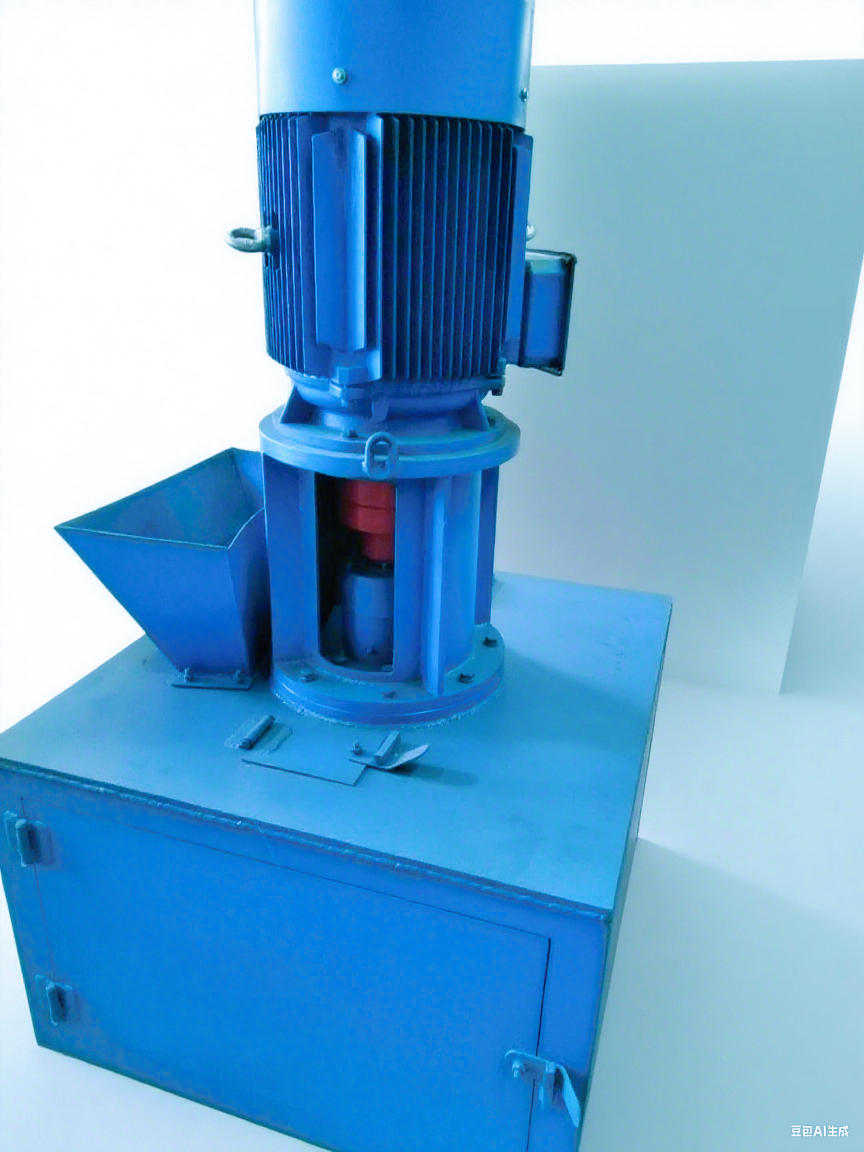

| Type number: | FQ600 |

| Cylinder inner diameter: | Phi 600 mm |

| Feed grain size: | The < 30 mm |

| Feed strength: | 1.5 ~ 4.0kgf / ㎝² |

| Feed water content: | < 14% |

| Rotor speed: | N=1450r/min |

| Production capacity: | 3 to 5t/h |

| Electrical power rate: | Y180L-4-22kw-50Hz-380V |

| Overall dimensions (L × W × H) : | 800mm×800×1300mm |

| Material description | The shell material is Q235-B plate; Inner cylinder: wear-resistant rubber; Chain is manganese steel; |

| Delivery instructions | The main machine of the grinder comprises a feeding port, a box, an inner cylinder, a motor and a bearing chamberEquipment operation manual, certificate |

| Equipment weight | 820kg |

Structural Composition

- Power system: Usually composed of a motor, pulley, V-belt, etc., it provides power for the operation of the crusher. The motor drives the main shaft to rotate through the V-belt, making the hammerheads or impellers and other components run at high speed to crush materials.

- Main shaft system: It is one of the core components of the crusher. The main shaft is installed vertically and fixed at the upper and lower ends of the casing through bearing seats. It bears the impact force and torque during the operation of the crusher and needs to have high hardness and toughness.

- Crushing components: Including hammerheads, blades, liners, etc. Hammerheads or blades are the main crushing tools, fixed on the main shaft, rotating at high speed to impact, shear and grind materials; liners are installed on the inner wall of the casing, forming a crushing cavity with the hammerheads, which plays a role in protecting the casing and assisting in crushing.