A Compound Fertilizer Urea Melt Granulation Production Line is a sophisticated and highly efficient system for producing high-concentration, high-quality granular fertilizers. Unlike traditional methods that use water or steam, this process leverages the molten state of urea as a binding agent, which results in a denser, more uniform product. This technology is especially suitable for creating compound fertilizers with a high nitrogen content, making it a key solution for modern agricultural needs.

Process Flow

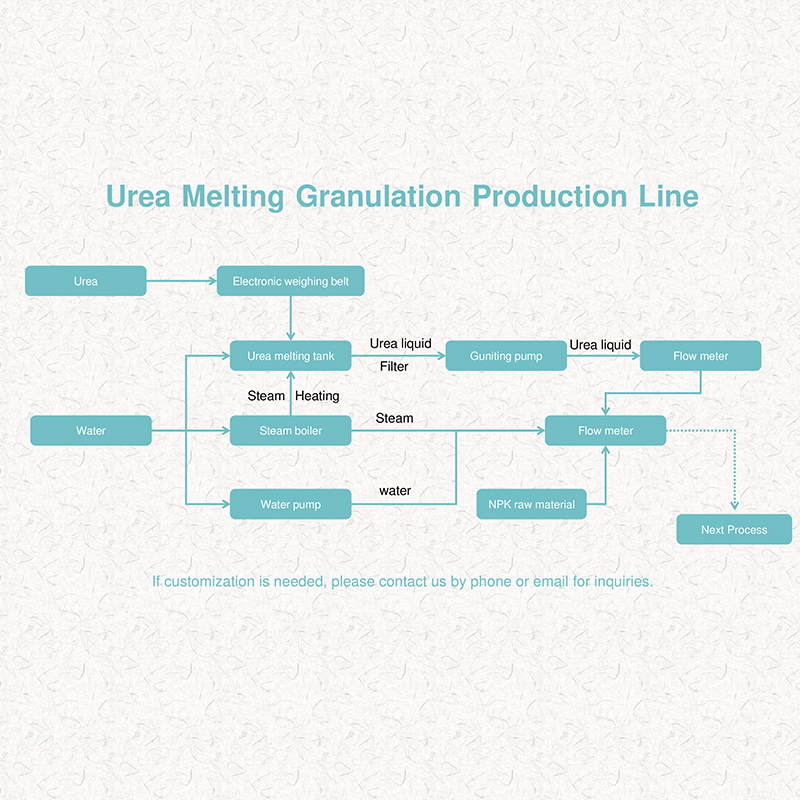

The production on this line involves a streamlined, integrated process:

- Raw Material Preparation: Solid raw materials, such as monoammonium phosphate (MAP), diammonium phosphate (DAP), and potassium chloride (KCl), are precisely weighed and mixed. Separately, urea is melted in a dedicated tank.

- Granulation: The mixed solid materials are fed into a rotary drum granulator. Simultaneously, the molten urea is sprayed into the drum. The molten urea acts as both a nutrient source and a powerful binding agent, causing the solid particles to agglomerate into granules.

- Cooling & Solidification: The hot, newly formed granules are immediately transferred to a fluidized bed cooler or a rotary cooler. Here, they are rapidly cooled to solidify the urea, which fixes the granule’s shape and strength.

- Screening & Classification: The cooled granules pass through a rotary screen to be sorted by size. Oversized granules are crushed and recycled, and undersized ones are also sent back for reprocessing, ensuring a high-quality final product with uniform size.

- Coating & Packaging: The final granules can be coated to prevent caking and improve their physical properties. They are then weighed and automatically packaged for distribution.

Equipment Composition

A typical Urea Melt Granulation Production Line includes the following essential components:

- Melting Tank: A crucial piece of equipment for melting urea.

- Rotary Drum Granulator: The core machine where molten urea is used to form granules.

- Fluidized Bed Cooler or Rotary Cooler: For rapid cooling and solidification of the granules.

- Rotary Screen: For accurate size classification.

- Crusher: To recycle oversized granules.

- Belt Conveyors: For seamless material transport between stages.

- Packaging Machine: Automates the final bagging process.

Characteristics

This production line is distinguished by its unique features, which offer significant advantages:

- High Nutrient Concentration: The process allows for the creation of high-concentration compound fertilizers, particularly those rich in nitrogen. This reduces transport costs and improves application efficiency.

- Excellent Granule Quality: The granules are exceptionally hard, spherical, and uniform. This makes them resistant to crushing and ideal for mechanized application.

- High Efficiency & Low Energy Consumption: The absence of a separate drying stage (as the molten urea already binds the particles) significantly reduces energy consumption and simplifies the overall process.

- Environmental Friendliness: Without a drying process, the line generates fewer dust emissions, making it a more environmentally friendly option.

Application Fields

The Urea Melt Granulation Production Line is a key technology for producing a variety of high-quality fertilizers for the agricultural sector:

- High-Nitrogen Compound Fertilizers: Ideal for crops that have a high demand for nitrogen.

- NPK Fertilizers with High Urea Content: Providing a balanced and efficient nutrient source.

- Specialty Fertilizers: The process can be adapted to include other nutrients and trace elements, creating tailored fertilizers for specific soil or crop requirements.

This technology is vital for enhancing agricultural productivity and providing farmers with advanced nutrient management solutions.

Key Selection Points

When choosing a Urea Melt Granulation Production Line, it’s essential to consider these critical factors:

- Production Capacity: Select a line that aligns with your business’s market demand and future growth plans.

- Raw Material Purity: The quality of the urea and other raw materials is crucial, as impurities can affect the granulation process.

- Automation Level: Determine the level of automation that fits your budget and operational needs. A higher degree of automation can increase efficiency but requires a larger initial investment.

- Energy Efficiency: Evaluate the energy consumption of the melting and cooling systems, as this will impact long-term operating costs.

- Manufacturer’s Support: Choose a reputable manufacturer that provides comprehensive after-sales service, including installation, technical training, and readily available spare parts.